INFINITY AX Fully Automatic Continuous Chocolate Tempering Machine

£13,500.00excl. VAT

"I purchased my first Keychoc AX two years ago, with an expansion in the business. I was so pleased with the workings of the machine, the wonderful finished product it allowed me to produce and the high level of support, that I purchased a second machine 12 months ago."

The INFINITY AX is a fully automatic, full-featured, continuous chocolate tempering machine, capable of tempering up to 200kgs/hr. You can use the AX to temper batches of chocolate from 12kgs up to 60kgs, even though it is only about the same size as a typical 24kg machine. It’s unequalled flexibility, ease of control and versatility make it the only chocolate tempering machine you’ll ever need.

The INFINITY AX is fully compatible with the INFINITY AML automatic moulding line, as is the INFINITY MX.

CHOCOLATE TEMPERING TIMES (from 42˚c)

- 12kg batch – 10 mins (usable chocolate 9kgs)

- 20kg batch – 15 mins (usable chocolate 17kgs)

- 40kg batch – 18 mins (usable chocolate 37kgs)

- 60kg batch – 22 mins (usable chocolate 57kgs)

All times are based on tests conducted with an ambient temperature of 19˚c.

OPERATING CHARACTERISTICS

- Minimum batch size 12kgs

- Tank capacity 60kgs

- Maximum hourly production rate of 200kg/hr of tempered chocolate

- Use down to 3kgs of tempered chocolate

- Flow rate of up to 600 kgs/hour

- Designed to work with inclusions up to 10mm

- Intuitive, touchscreen operation

- Full PLC control

- Foot-pedal operated manual dosing

- Automatic programmable dosing (up to 999 deposits)

- Programmable start timer

- Adjustable flow control

- Maximum recommended environment temperature is 22˚c

- Optional vibrating table (heated or unheated)

- Optional INFINITY depositing head

- Optional transfer pipe if used as a feeder tank

- Compatible with INFINITY AML automatic moulding line

DESIGN & CONSTRUCTION

- Removable auger

- Supplied with foot pedal

- Automatic pump reverse to empty auger tube and outlet pipe

- Outlet pipe can be swivelled to fill large moulds alongside machine

- Cover for night mode to prevent contamination

- Lockable castors for ease of moving

- High precision temperature probes to give control to 0.1˚c

- Electronic contact heaters for precise, responsive control

- Fully insulated tank for energy efficiency

- Gas cooling (R1270 for UK/EU, R452a for USA/rest of world)

- All contact parts made from stainless steel 304 (except auger)

- Single phase supply, 13 Amp, 208-240V, 50/60Hz (please note minimum RCD rating in the Technical Specifications section)

CLEANING

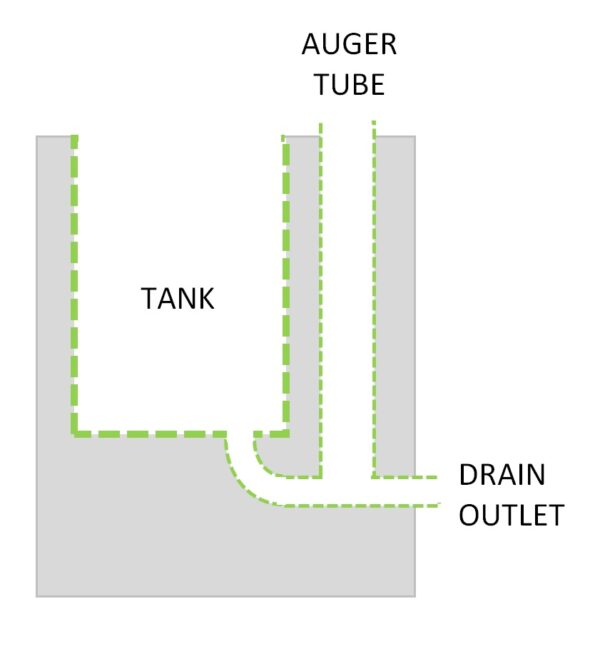

The INFINITY AX is fitted with a removable auger and a very convenient drain outlet at the rear of the machine. The auger is easily removed from the top of the machine, allowing any remaining chocolate to be shaken off directly into the tank with no mess. The schematic image above shows how the connecting pipes have been specifically designed to make cleaning as easy as possible. As a result, fully cleaning the machine can be completed in just 15-20 minutes (excluding drying time).

- Low-level drain to efficiently empty tank and clean pipes

- Auger can be easily removed directly above tank to avoid mess

- Outlet pipe can be removed and dismantled for easy cleaning

Our cleaning video features an Infinity BX, but the cleaning process for the AX is exactly the same.

WORKING WITH NON-STANDARD CHOCOLATES

Bean-to-bar, craft, dairy-free, low-sugar and added protein are just some examples of growing trends in the chocolate confectionery sector. But these ‘non-standard’ chocolate grades are often more difficult to work with than a typical Callebaut standard grade and not all tempering machines can cope with the challenges they present! However the Infinity AX can, due entirely to the ability to modify the operating parameters of the machine in order to adapt it to a particular chocolate.

If you know or suspect that your chocolate may fit into this category, then Keychoc offer a service whereby we will do all the hard work of figuring out the optimal settings for you using a sophisticated temper meter and plenty of temper and moulding tests. The process takes several days and you will receive a detailed report showing our findings. Please call us for further information.

Note that if you are using standard chocolate grades, the AX will work without the need for any adjustments. Just set the right working temperature and you’ll have perfectly tempered chocolate, every time!

Our next generation INFINITY Series automatic tempering machines have been specifically designed to serve as the backbone of a versatile, modular chocolate production system and are manufactured in the UK.

- Operating capacity: min 12kgs - max 60kgs

- Maximum hourly production: 200kgs/hr of tempered chocolate

- Suitable for Inclusions up to 10mm

- Max flow rate: 600 kgs/hr

- Removable auger

- Direct heating

- Digital temperature control

- All stainless steel

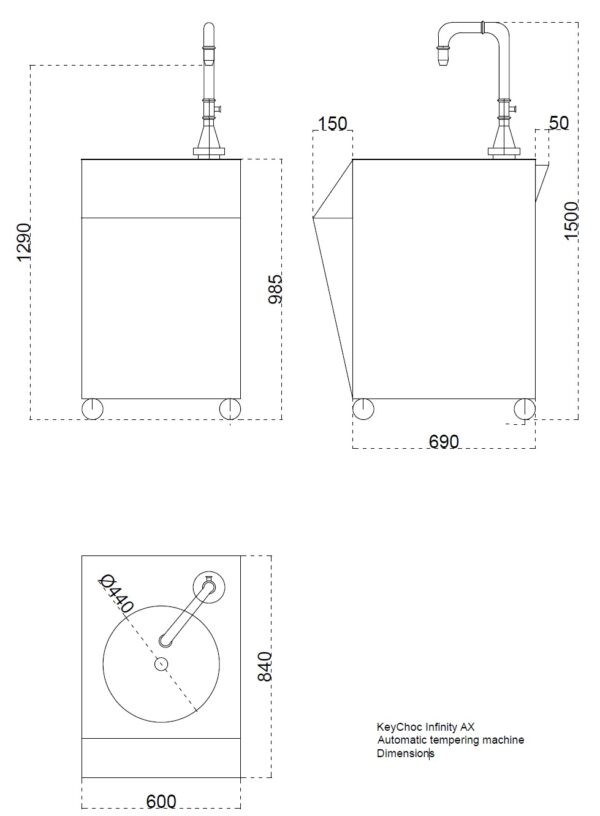

- Dimensions: (W) 600mm x (D) 780mm x (H) 940mm

- Dimensions: (W) 800mm with vibrating table fitted

- Single phase, 208-240V, 50/60Hz

- Max Power Consumption: 2.4 kW

- Max Current: 10 Amps

- If you are connecting the AX to a single phase power source fitted with an RCD, then the RCD must be rated for 300mA, not just the standard 30mA normally found in domestic environments

- Refrigerant: R1270 for UK/EU, R452a for USA/rest of world

- No plumbing necessary

- OPTIONAL vibrating table

- OPTIONAL depositing head