Infinity BT150 Automatic Batch Temperer

£12,600.00excl. VAT

“When we first started we were using Bain Maries to melt chocolate, which was a complete nightmare. We then moved to a machine from another chocolate equipment company which was also unsatisfactory and I ended up having to throw chocolate away regularly. Six months ago we purchased a BT75 Automatic Batch Tempering Tank from KeyChoc and I can honestly say it was the best £6,000 I have ever spent. The machine is a dream and makes me ecstatically happy. I love it so much I want to have its babies! I even love it more than I love my car and that’s saying something!

We get through kilos of coatings every week and use the KeyChoc machine for all our bakery requirements, especially Millionaires Shortbread, Tiffin, Chocolate Crispy Crunch etc. The machine makes my life so easy and saves time and money. It’s quick and efficient and we’re not throwing away chocolate all the time. Now we can top a rack of Millionaires Shortbread (100 bars) in less than 15 minutes.

The machine is a joy to use and it works perfectly. A KeyChoc engineer installed it when we first purchased the machine and talked us through how to use it. Since then it has been wonderful and has definitely helped grow my business.”

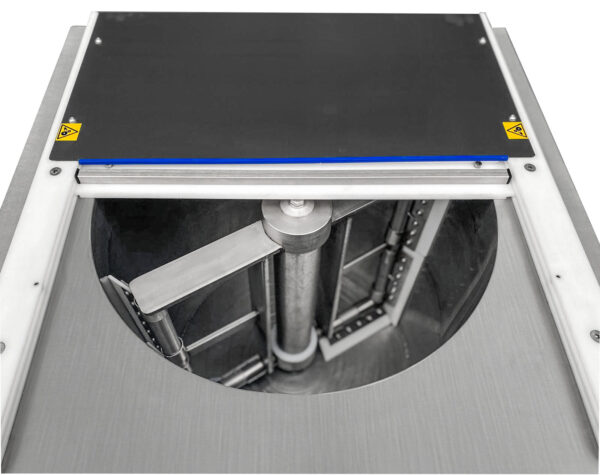

If you currently temper your chocolate manually, or if you simply require more tempering capacity, our new KeyChoc fully automatic batch tempering tank could be just what you need. The Infinity BT150 has a tank capacity of 150kgs.

It is ideally suited for use as an independent source of tempered chocolate to feed an enrober, one-shot depositor or even in a bakery for coating biscuits or traybakes.

- Take the mystery out of tempering and free up the time of your most experienced staff

- Achieve consistently tempered chocolate every time

- Hold temper for long periods of time (due to stirrer action)

- PLC-driven with touchscreen controls

- Typically 50% less water consumption than other similar machines

- Insulated water jacket

- Non-immersion heaters for easy maintenance

- Designed with easy cleaning in mind

- All stainless steel construction

The BT150 batch tempering machine needs to be connected to a cold water supply.

- Fully automatic batch tempering

- 150kg capacity

- PLC-driven with touchscreen controls

- Forced cold water cooling

- Scraped surface stirrer

- Pulsed water inlet control for maximum efficiency

- Typically uses 50% less water than competitive tanks

- Good access for cleaning

- Constructed from high quality stainless steel

- Enclosed insulation

- Power: 3 Phase Supply Required, 380-460V, 16A, 50/60Hz

- 2 x 2.2 Kw tube heaters (non-immersion for easy maintenance)

- Dimensions: (W) 800mm x (D) 800mm x (H) 1200mm

- Plumbing needed (infeed/outfeed)